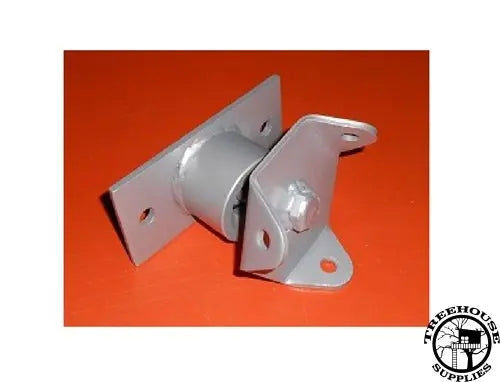

TIRE SWING SWIVEL - RESIDENTIAL

TIRE SWING SWIVEL - RESIDENTIAL

- Free US Shipping on Orders over $350 (Continental US only)

Compatible with

Tire Swivel - Residential

Grease the Tire Swivel before using. Tire Swivel must be installed in a bay without any other components. For tire swings, extend surfacing in a circle whose radius is equal to the height of the suspending chain or rope, plus 6 feet in all directions. Only use this tire swivel in residential settings. Place tire swivel on wood beam and mark holes with pencil or pen on wood. Drill two 3/8” holes. Then, bolt tire swivel to wood beam with 3/8” bolts with the length depending on thickness of the wood, plus two flat washers, one on top and one on the bottom of the bolts and secure with a 3/8” nylock nut. (Bolt, washers and nuts are not included.) Put bolts and washers through beam so that nuts are on the bottom of top beam, and so that the bolt is attached with no more than two thread showing beyond the nut. This will prevent a protrusion on the top beam. You will need to use S-hooks or H shackles from the chain to the swivel. Make sure the S-hooks are closed to within .04 to meet ASTM safety standards. To do this you will need to use our S-hook pliers or a regular pair of channel lock pliers. Close according to Fig A1.19 for Fastening Devices. WARNING: Once the S-hooks have been opened they will have to be replaced to avoid injuries from coming open and/or breaking. Make sure that if you are using shackles they are also tightened correctly. No bolts should protrude over two threads past its nut.

Safe Use: This swivel is intended for use by children 2 - 12 years old only. Adults should supervise children at all times. Do not allow children to use unsafely. Do not allow equipment to be used if damaged or wet.

Maintenance: Do the following to reduce the chance of serious injuries. At beginning and end of each play season and once a month during play season, check for rusty or worn chain. Carefully check hole around fastener to look for wear. Check for vandalism. Check to make sure s hooks and/ or H-shackles are closed properly. Check spinning action and make sure there is no binding, and using a grease gun put a sufficient amount of standard grease in the hanger to allow the hanger to swing freely. We have used a McKay Molybdenum Disulfide grease cartridge, but any standard grease cartridge from any auto part store should be sufficient. Make sure all nuts and bolts are secure and not worn. Look for loose parts, cracks in metal or rust. Replace parts necessary for safe use.